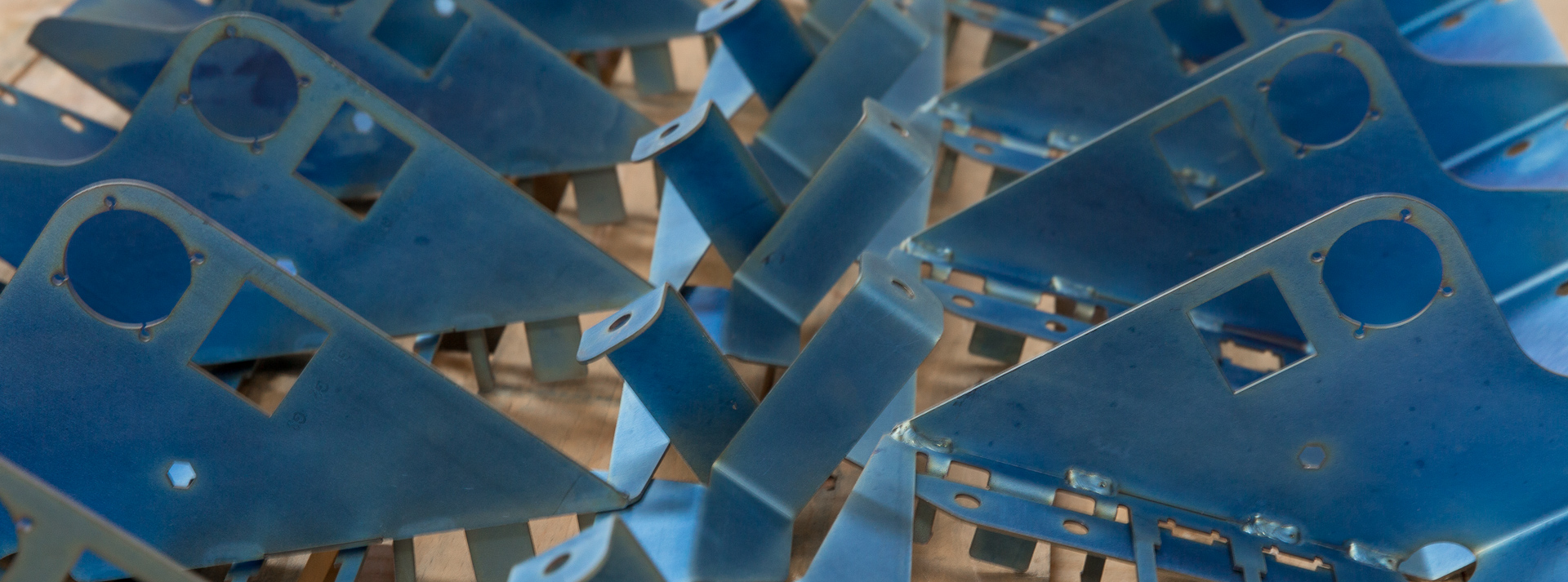

Zinc Nickel Alloy Plating

Zinc-nickel plating involves zinc and nickel being co-electro deposited on to components. Zinc-nickel plating can be passivated to further improve its corrosion resistance.

Zinc-nickel alloy plating is superior to standard zinc plating and is seen as an alternative to cadmium plating. In recent years as technology has improved, it has become a desirable cost effect method of improving the corrosion resistance and life span of the plated component.

Zinc Alloy UK ltd offer zinc-nickel plating at a variety of thicknesses. Unpassivated or Trivalent clear passivated (Hexavalent chrome free) which complies with the European Unions ‘End of Life Vehicle’ directive.

Key Properties of Zinc Nickel Alloy Plating

- Exceptional corrosion resistance

- High temperature resistance

- Exceptional corrosion resistance even after heat treatment

- Even Deposit Distribution

Capabilities / Capacity

We have a 350Kg lifting capacity. Lengths up to 1.6 metres.

Further Technical information

The plated coating generally consists of 11 to 16% nickel and the remainder as zinc (many specifications allow a larger range, but best performance is usually found in this range).

Standards for zinc-nickel plating typically require unpassivated parts coated with 10µm of zinc-nickel to withstand 500 hours or more of neutral salt spray testing before red corrosion. For comparison zinc plated and passivated parts of a similar thickness are expected to achieve only 120 hours – which is considerably less.

Zinc-nickel has good unpassivated corrosion resistance, although it can be improved even further with passivates and top coats. By comparison zinc plating is very reliant on the passivation and topcoating for protection. In this way, zinc nickel may perform much better than zinc for higher temperature applications (passivates lose this effectiveness at elevated temperature).

Zinc nickel bridges the galvanic gap between steel and aluminium, reducing the risk and rate of galvanic corrosion. In this way, it works similarly to cadmium. Zinc-nickel is still sacrificial and so provides some protection to the steel even in the event of small scratches, cracks etc.

If you are interested in our Zinc Nickel Alloy Plating service, then please contact us on: 01524 381 611 or email us here.