Chemical Blacking

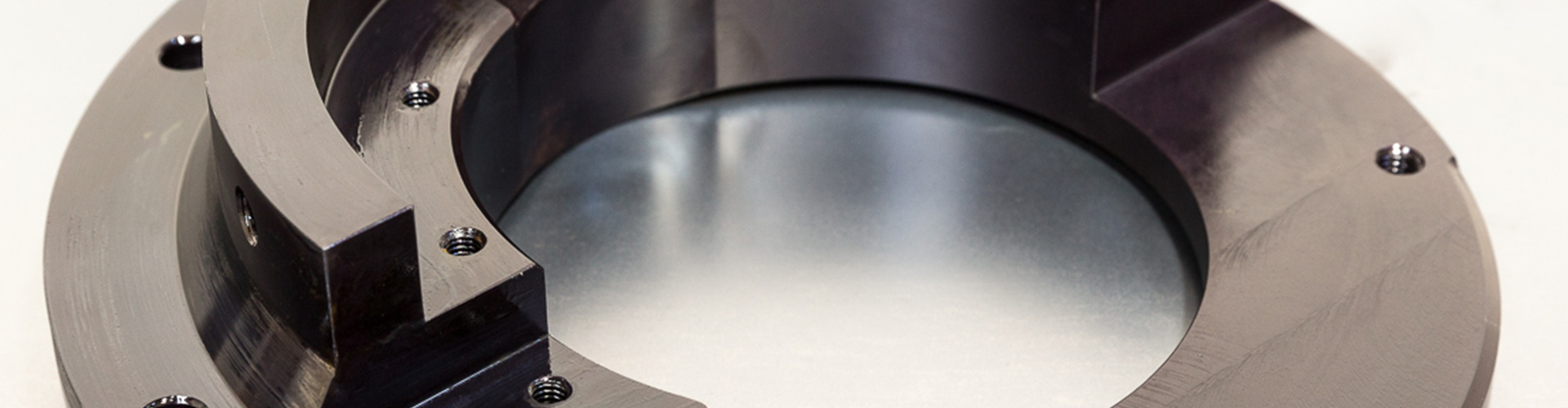

Chemical blacking is used to treat steel items to give a black oxide film coating.

Chemical Blacking ( Black Oxide Coating) provides an oxide layer which is an integral part of the steel surface. The parts are finally immersed in an ultra thin film dewatering oil which is absorbed by the oxide surface.

Chemical blacking enhances the appearance of the part whilst making no dimensional or metallurgical changes to the part in question.

From tool pieces to automotive parts, the finish will not chip, flake, rub or peel off and the effects of the blackening include reduced light glare or reflection and improved lubrication characteristics.

Key Properties of Chemical Blacking

- it does not change the dimensional tolerances of machined components.

- it provides an aesthetically pleasing engineering surface.

- it provides improved corrosion resistance.

- it provides a lubrication layer which reduces the effects of galling and fretting corrosion.

Capabilities / Capacity

We have a 350Kg lifting capacity. Lengths up to 1.6 metres.

If you are interested in our Chemical Blacking service, then please contact us on: 01524 381 611 or email us here.